BIOLOGICTM SR2

FOOD PROCESSING ODOR

Successful Results Featuring BIOLOGICTM SR2

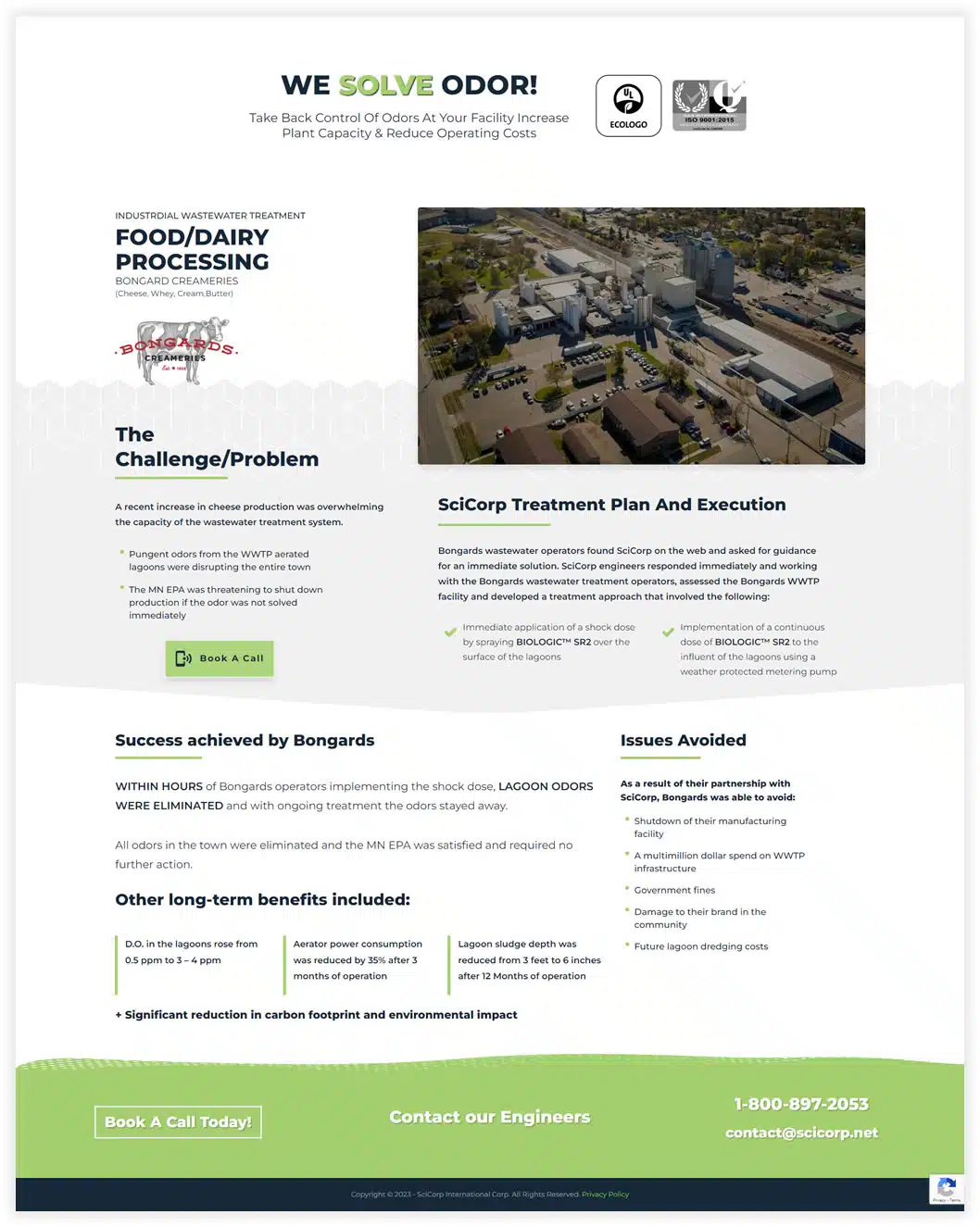

Food Processing

Bongards wastewater operators found SciCorp on the web and asked for guidance for an immediate solution. SciCorp engineers responded immediately and working with the Bongards wastewater treatment operators, assessed their WWTP facility and developed a treatment approach that involved the following:

Dairy Processing

Shortly after implementing the BIOLOGICTM SR2 treatment, Parmalat engineers reported a very significant reduction in odor complaints caused by the sludge storage cells and the return activated sludge.

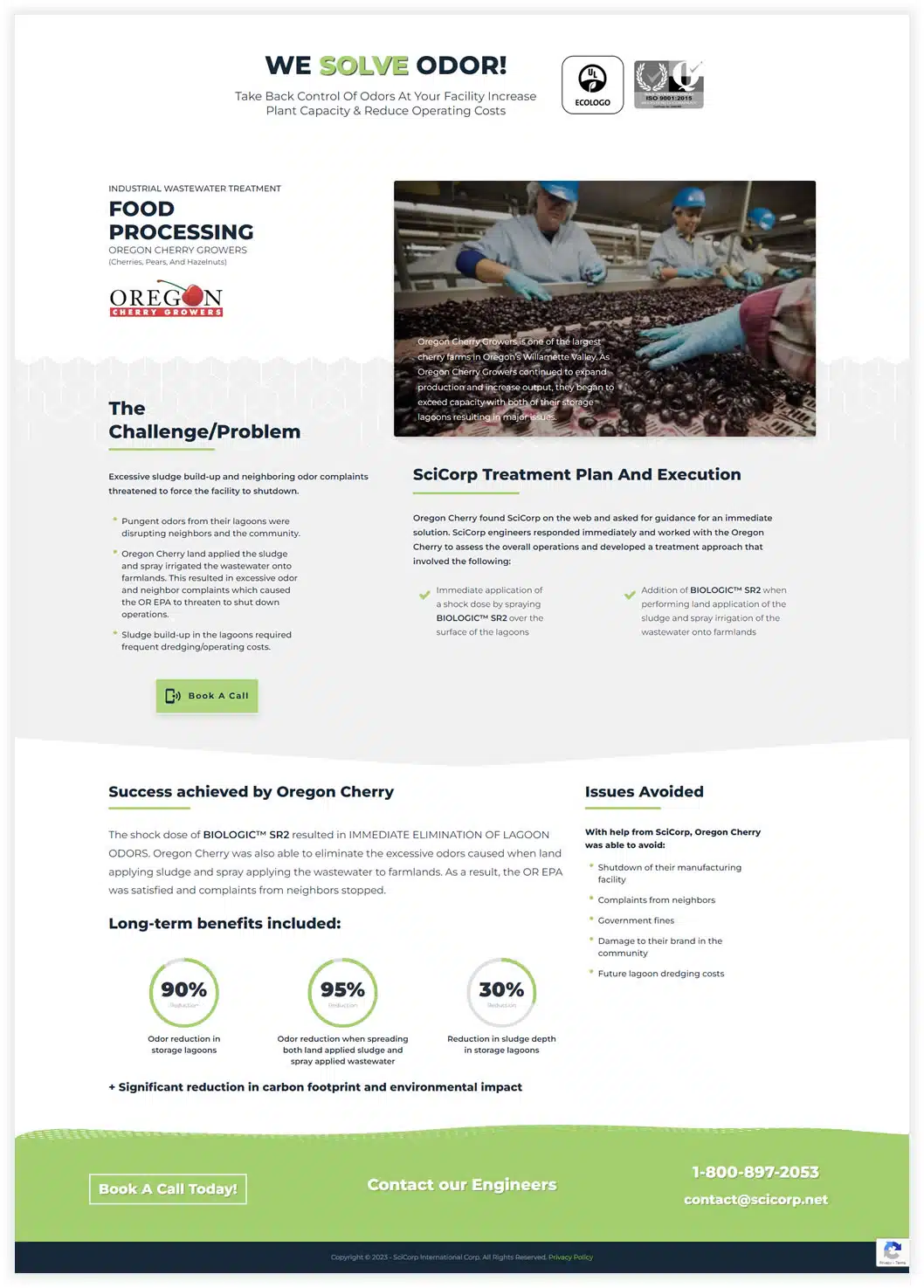

Fruits & Vegetables

Oregon Cherry contacted SciCorp for guidance for an immediate odor solution. SciCorp engineers responded immediately and worked with the Oregon Cherry to assess the overall operations and developed a treatment approach that involved the following:

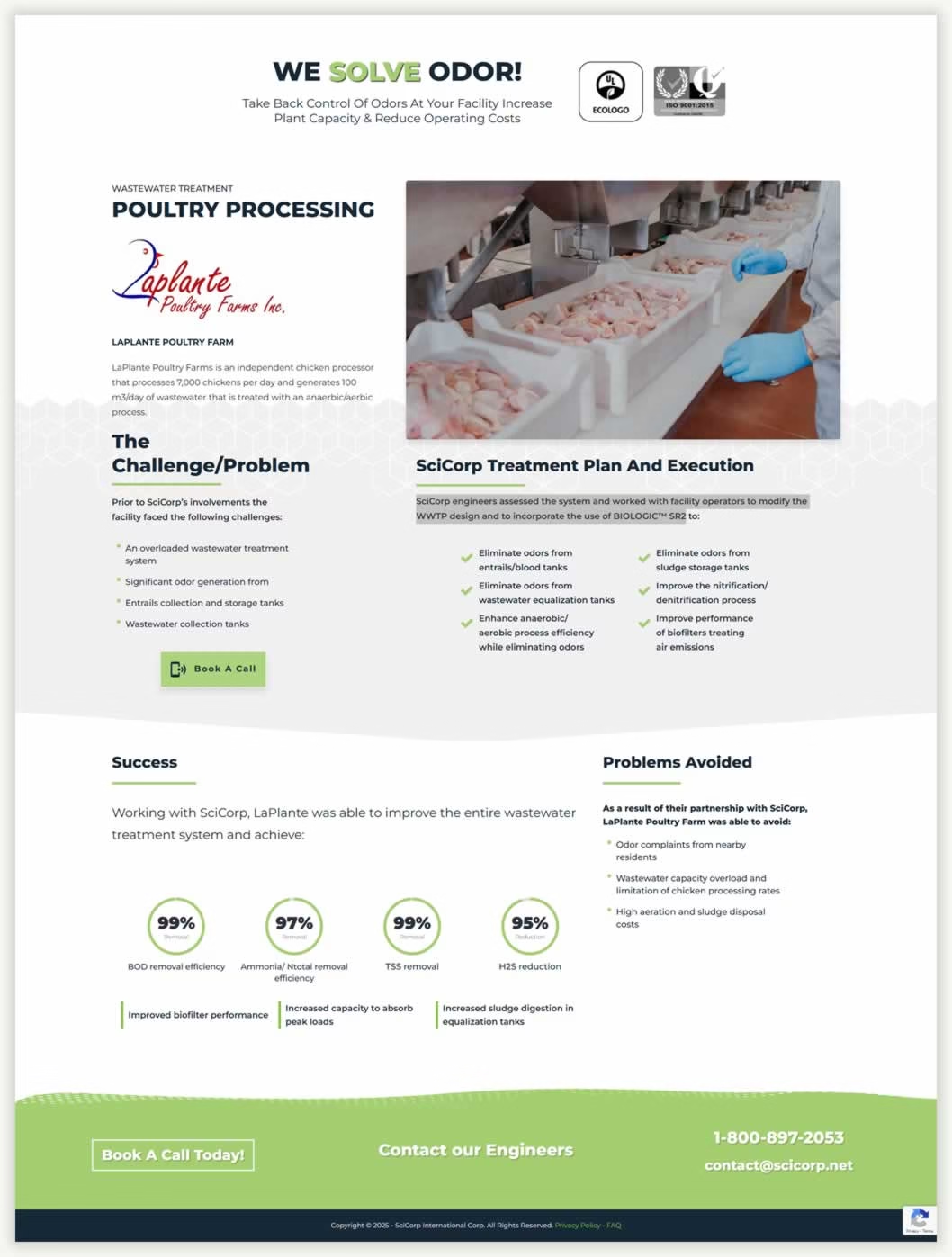

Dairy Processing

LaPlante Poultry Farms is an independent chicken processor that processes 7,000 chickens per day and generates 100 m3/day of wastewater that is treated with an anaerbic/aerbic process. SciCorp engineers assessed the system and worked with operators to modify the WWTP design and successfully incorporate the use of BIOLOGIC™ SR2.

Large Chicken Processor

Treatment Plan & Execution

SciCorp worked with plant operating staff and developed a treatment approach using SciCorp technology to address operating challenges. SciCorp recommended the following:

Poultry Processing

Working with SciCorp, Maple Lodge operators were able to optimize their wastewater treatment facility resulting in the elimination of odors, elimination of WWTP upset occurrences and a measurable reduction in operating costs.